How to Start Manufacturing Operations in Mexico?

One of the main challenges for foreign companies to establish in Mexico, is they think that some aspects can be done similarly to how it is done in their country of origin or assume it can be done in a specific way without consulting with the experts. This is where a shelter company in Mexico becomes very useful.

It is very important to note each country counts with different laws, regulations, and procedures. Therefore, starting and running operations in Mexico is not complicated, but it is different, and for this reason it is important to be informed beforehand, get help from the experts, and understand what and how it must be done.

Below you will find some main steps you must consider for starting manufacturing operations in Mexico.

1) Define your business model scheme

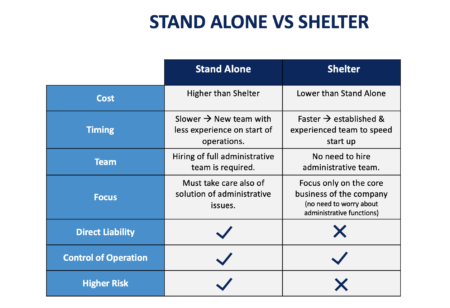

- Standalone: The foreign company creates a new entity in Mexico, with total control of all operations including administrative functions, and with total independence from third parties.

- Joint Venture: There is an equal partnership between a Mexican manufacturer and a foreign company. Within this model, the foreign company faces more risks and liabilities than a shelter business model and provides an immediate knowledge base and experience.

- Shelter: A company is hired by another to manage all administrative and legal tasks, while the other company can focus on its core business. Through a shelter company in Mexico, there is no need to hire personnel for administrative functions. Shelter companies can facilitate the start operations without the need for an established and legal presence in the country, in a faster way and through a risk mitigation approach.

- Contract manufacturing: A company is hired by another to produce goods or provide a service. Nevertheless, the company does not have full control and oversight of production and quality assurance. Contract manufacturing is not as common in Mexico as in other countries as Mexico materials manufacturers most of the time do not need help to approach the US markets, so there is less need in Mexico to partner with larger foreign investors.

There are different options in which a foreign company can operate in Mexico, depending on the business model that fits best their needs:

2) Company Incorporation, Permits, and Programs

Depending on the business model you choose, the company must proceed with obtaining the required registrations and permits. For example, in a standalone business scheme, the first step for the company is to incorporate a new entity in Mexico, and register it before the Public Registry of Commerce, Tax Authorities, and Social Security among other registrations. Or to obtain the Importers Registration, IMMEX Program, or any other program that applies. An experienced partner can support your company in determining which foreign trade incentive programs you can benefit from.

3) Site Selection

Once you have decided to establish in Mexico, the next step is to decide in which State. The main deciding factor for most companies is the location of their clients or suppliers. Other companies also take into account if they want to be in the north of Mexico right on the border with the United States or on the coast. Furthermore, the incentives received from the government can also be a deciding factor.

Afterward, you must decide between leasing or building in Mexico. Depending on the needs of your company you can decide to build a new facility from scratch, find a built–to–suit lease, or make a small improvement to an already existing building. The cost to lease industrial space in Mexico will vary highly on which region of Mexico, or if it is located in an industrial park, among other factors.

- Leasing and buying costs in Mexico:

The cost to lease industrial space in Mexico can be as low as $0.40 USD per sq. ft. per month. And the cost to buy and industrial land in Mexico can be as low as $2.50 USD per square feet.

4) Recruiting and Training of Personnel

Recruiting the first employees is an important step. The recruiting process in each country is different, and in Mexico, it can be considered as a complex process. Therefore, looking for support from experts is always a good idea. An experienced shelter company in Mexico can speed up and facilitate the recruiting process, personnel ramp-up, and training for employees.

5) Building your supply chain in Mexico

Mexico counts with an important supply chain network for various industries, as it is home to different industry clusters. Therefore, it is important to establish with the material you will source locally and which from abroad, and make sure any new suppliers meet the company’s quality standards.

6) Start of Production

Once you have covered the above-mentioned steps, the logistics process has been planned, the equipment has been installed, the testing stage has been completed, it’s time to proceed with the start of production.

Is your business considering moving to Mexico? Mexcentrix can help you by facilitating the process through a smooth start and running of operations. Contact us!