How can a Shelter Service Company help you?

Have you heard of a Shelter Service Company?

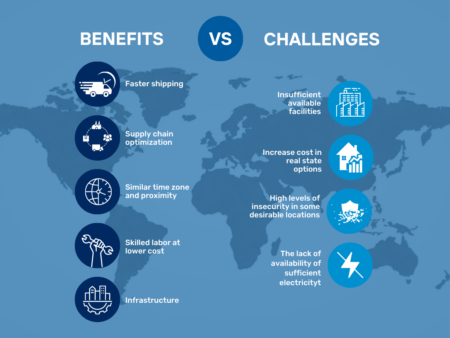

With its strategic location, skilled workforce, and favorable trade agreements, Mexico is an attractive destination for nearshoring. However, entering a new market can be complex, especially for international investors navigating unfamiliar regulatory frameworks and operational challenges.

In this dynamic environment, leveraging the expertise of a shelter company has emerged as a strategic approach for investors looking to establish a presence in Mexico while minimizing risk and maximizing efficiency.

Understanding Shelter Companies

A Shelter Service Company offers comprehensive solutions for foreign companies seeking to establish operations in Mexico. They specialize in providing infrastructure, administrative support, compliance services, and operational expertise.

Each shelter company, counts with different scope of services, nevertheless in its majority investors can benefit from the following services:

- Start- up services: Includes the site selection process, to help foreign companies find the best location for their operations, in addition to obtaining all permits and licenses to operate in Mexico.

- Human Resources: Recruiting and managing a skilled workforce is essential for business success. Shelter companies assist with hiring, training, payroll administration, and employee benefits, allowing investors to focus on their core business activities.

- Foreign trade: Ensuring the arrival of raw materials on time is critical for optimizing operational efficiency and minimizing costs. Shelter companies help streamline foreign trade operations, while helping your company be 100% compliant with local laws and regulations.

- Tax, Accounting & Finance: Operating in Mexico requires in depth knowledge of the Federal Fiscal Code and local regulations, partnering with an experienced company can help you avoid troubles and fines with tax authorities.

- Legal Compliance: As mentioned before, navigating Mexico’s regulatory framework can be challenging for foreign investors. Shelter companies possess in-depth knowledge of local laws, regulations, and tax requirements. Thus, ensuring that clients remain compliant at all times.

- Government Incentives: Mexico offers attractive incentive programs at both federal and state levels, for foreign companies. From land or cash grants, tax incentives, licenses to workforce training programs. Each state offers different incentive package to investors depending on the amount to be invested and employment generation. Shelter companies can support in the incentive negotiation process and proof required process.

- Risk Mitigation: Operating in a foreign market entails various risks, including legal, financial, and operational risks. Shelter companies provide risk management services, including insurance coverage, contingency planning, and crisis management support.

Maximizing Returns with a Strategic Approach

Investing in Mexico offers compelling opportunities for growth and expansion, but success requires careful planning, execution, and risk management. By partnering with a reputable shelter company, investors can mitigate challenges, accelerate time-to-market, and maximize returns on their investment.

As global competition intensifies and market dynamics evolve, proactive investors are increasingly turning to shelter companies to gain a competitive edge and capitalize on Mexico’s vibrant economy. Whether entering the market for the first time or expanding existing operations, leveraging the expertise of shelter companies can position investors for long-term success in Mexico’s dynamic business landscape.

If you’re intrigued by the benefits of using a shelter service company and want to have further information, we encourage you to Contact us!

Mexcentrix shelter services can help you run operations efficiently, while at the same time reducing risks and costs.

Navigating the legal and regulatory landscape in Mexico can be difficult, particularly for foreign companies unfamiliar with local laws and regulations. Failure to comply with legal requirements may result in fines, legal disputes, and reputational harm. Common areas of oversight include labor laws, tax regulations, and intellectual property protection.

Navigating the legal and regulatory landscape in Mexico can be difficult, particularly for foreign companies unfamiliar with local laws and regulations. Failure to comply with legal requirements may result in fines, legal disputes, and reputational harm. Common areas of oversight include labor laws, tax regulations, and intellectual property protection. Effective communication is critical in nearshoring to ensure a successful operation. Language barriers and communication styles can present significant challenges. While English is widely spoken in Mexico, many employees do not speak English or are not fluent. Furthermore, differences in communication styles and expectations can cause misunderstandings and misinterpretations.

Effective communication is critical in nearshoring to ensure a successful operation. Language barriers and communication styles can present significant challenges. While English is widely spoken in Mexico, many employees do not speak English or are not fluent. Furthermore, differences in communication styles and expectations can cause misunderstandings and misinterpretations. Mexico’s infrastructure varies greatly, and businesses may face challenges with transportation, logistics, and access to reliable utilities, for example, power its availability for high requirements is currently limited in many parts of Mexico. Underestimating infrastructure requirements can lead to production delays, increased costs, and operational inefficiencies.

Mexico’s infrastructure varies greatly, and businesses may face challenges with transportation, logistics, and access to reliable utilities, for example, power its availability for high requirements is currently limited in many parts of Mexico. Underestimating infrastructure requirements can lead to production delays, increased costs, and operational inefficiencies.